2024-03-11

Application of Membrane Dryer in CNC Machine Tool

The equipment manufacturing industry is the cornerstone of a country's industry. It provides an important means for the development of new technologies and new products and modern industrial production. It is an indispensable strategic industry. With the rapid development of China's national economy, the market for high-grade CNC machine tools put forward a large number of urgent needs.

High precision CNC machine tools in the air bearing and grating ruler, the need for high cleanliness of the dry compressed air drive and protection. The compressed air with insufficient dryness will greatly affect the moving accuracy of the air bearing and the measurement accuracy of the grating ruler,

CNC drilling machine (PCB machine) is one of the typical equipment. With the increasing level of electronic integration and complexity, the size of PCB board is getting smaller and smaller, the number of layers is getting higher and higher, the processing degree is becoming more and more complex, and the requirements for CNC drilling machines are getting higher and higher. The CNC drilling machine is developing in the direction of high speed, high precision and high stability. The spindle speed of the international CNC drilling machine has reached 350000 rpm, and the spindle speed of the domestic mainstream CNC drilling machine is 16-200000 rpm. The spindles of the CNC drilling machine are all made of air bearing. This puts high demands on the quality of the gas source. The poor quality of the gas source will have the following adverse effects: 1. The main shaft is damaged; 2. The processing accuracy is reduced and the product rejection rate is increased; 3. The production efficiency is reduced; 4. The possibility of sudden shutdown is increased.

Now on the market 2-axis, 4-axis, 6-axis CNC drilling machine, each spindle air bearing gas consumption is 100L/Min, this part of the gas source quality requirements are very high, can not have liquid oil, water and impurities. According to the ISO8573.1 standard, the air quality needs to reach 1-4-1 level, that is, solid particles ≤ 0.1 microns, dew point temperature ≤ 3 ℃, residual oil content ≤ 0.01mg/m3. If there is liquid oil and water in the gas source, the spindle of the CNC drilling machine without a dryer is easily damaged. It takes about 20000 yuan to repair a spindle, which will be borne by the manufacturer.

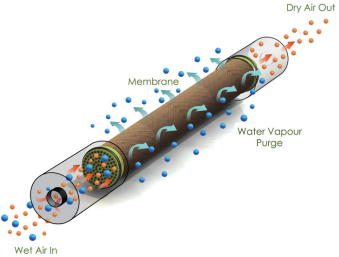

Membrane dryer with CNC drilling machine has a great advantage. The reasons are as follows: 1. The size of the permeable membrane dryer is small and can be integrated with the filter. Does not occupy the space of the drilling machine. 2, no power supply, maintenance-free. Pure physical characteristics, no movable parts. 4. It can provide a stable dew point to ensure the normal operation of the equipment. Low noise, long-term continuous operation.

Tianjin Lianke Sichuang Technology Development Co., Ltd. distributes oil-free compressors, filters and dryers, which have been widely used in medical, pharmaceutical, aerospace, energy, rail transit, education and scientific research and other industries.

Our company is a high-tech enterprise recognized by the Tianjin Municipal Government. It has a professional R & D team and has obtained several national intellectual property certificates. It can provide integrated services of design, R & D, production and sales according to customer requirements. Over the years, adhering to the "quality-oriented, technology first, service leading" business philosophy, and has been determined to continue to innovate, improve the management system, and constantly enhance the competitiveness of products. Welcome friends from all walks of life to contact and cooperate to discuss!

Contact: Wang Gong

Tel: 022-83713191-8011

13312151829

Email: tonywang@linkstrong-tech.com

Dryer, CNC, Drilling Machine, Compressed Air

Previous Page

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11