2024-03-11

Influence of Compressed Air Quality on Food

Compressed air is an important tool widely used throughout the food industry. Understanding the composition of the compressed air used in the plant is key to avoiding product contamination. Your task is to evaluate the activities and operations that may damage the product, the extent to which the product is damaged, and the possibility of product damage occurring. Assessing product contamination is a multi-step process. During this process, you must identify important risks, prioritize them, and take reasonable measures to eliminate or reduce the chance of harm to the product, especially to consumers. The chance of serious harm.

Sources of potential product hazards

Normal ambient air contains millions of inert particles per cubic meter, 5-25 grams of water, 1-5 grams of oil and tens to hundreds of bacteria. In addition, the system itself can be a possible source of contamination, including pipe scale and rust, polymer shredded particles, rubber gaskets, sealing tape, metal chips at pipe cuts, and even particles in charcoal filters and desiccant tanks. Sometimes, condensed water or liquid oil already present in the system will form an aerosol or vapor, thereby forming another source of pollution.

Risk Assessment

In general, the steps to assess the risk of contamination of a product are as follows:

1, identification of potential hazards,

2, assess the risk of injury

3, assess the adequacy of existing controls,

4, Evaluate whether additional controls are needed

5. Schedule regular checks to see if the controls are working properly

Identify hazards

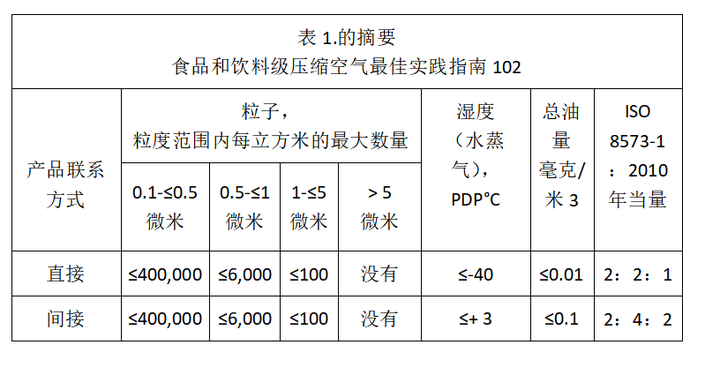

Once many components of the ambient air enter the compressed air stream, they become pollutants. For ease of discussion, we will omit airborne microorganisms. When compressed air components have a harmful effect on the product, they are considered compressed air pollutants. ISO 8573.1:2010 contains the purity levels of the components/contaminants in the compressed air, as shown in Table 1.

In addition, the British Retail Association and the British Compressed Air Association have jointly developed a code of practice for the food and drink industry. This specification combines the selection of ISO 8573-1:2010 purity classes to present productsdirect contactCompressed air and productsindirect contactRecommendations for compressed air are shown in Table 1.

These two norms cover the most obvious hazards. According to the guidelines, compressed air quality should be tested and verified at least twice a year or according to the manufacturer's recommendations. Whenever maintenance work or any activity that may affect air quality is performed on the compressed air system, additional tests must be carried out. The guidelines recognize the importance of compressed air quality and state that in addition to hazard analysis and critical control point plans, compressed air should now be part of the prerequisite plan. Whenever maintenance is performed, a representative selection of air outlets should be tested to confirm that the compressed air meets the relevant purity level.

Assess Hazard Risk

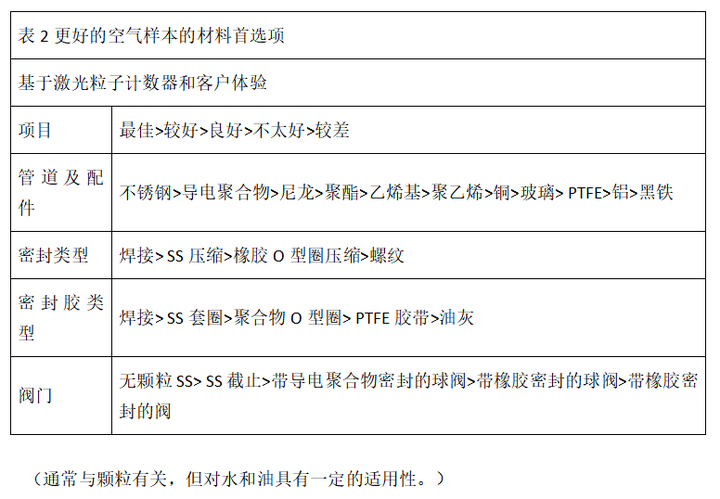

The following table lists the materials of the various parts of the compressed air system that constitute the best sampling environment. This table may be useful in assessing the risk that the system is currently out of specification.

Evaluate existing controls

Up-to-date regulations and publications will ensure knowledge of the relevant standards. For the current state of the existing controls, the quality of compressed air can be monitored in two ways, by testing all key application points, or by testing random representative parts. Although it is more expensive to test all points, this is the only completely accurate method, because contamination can occur at any particular point without affecting other nearby points. What could happen is that the untested bit ends up being contaminated.

The sampling strategy should be robust to ensure consistent air quality to all points of use. There are several sampling options to consider when evaluating the system and its controls:

• Determine the percentage of sampling points to be tested in a given time period, e.g., 100, 50%,25%, etc.

· Take three samples: one close to the compressor, one halfway through the system, and one as far away as possible from the purification

• Sampling immediately before and after a filter change to weigh the worst case against the best case. The data obtained after 3-4 filter changes can be used to establish a trend analysis.

Review control effectiveness

The control efficacy will be apparent upon receipt of the air sample test results. If the content of the pollutant falls within an acceptable threshold (by industry), control is sufficient. However, if the pollutant meets or exceeds the set standard, you can choose to reevaluate whether the limit setting is improper, or add other controls, such as using a point filter.

Evaluate whether additional controls are required

If the control efficacy proves to be insufficient in the previous step to achieve the required air purity level, it is clear that other controls are required. Information on options may be provided by industry or across industries, but the principle is to either add controls where there are no controls (such as adding refrigeration dryers where there are no controls) or add controls on existing controls (such as adding desiccant to dryers).

Scheduled periodic review

This involves periodic reviews, the time frame of which is specified by industry standard setters. Quarterly testing is a good place to start in industries and regions where testing is not strictly enforced. This may provide a baseline where no historical data exists, or may provide an accurate current assessment if there is an existing record. The compressed air system is not static, but dynamic, and always changing. Parts are faulty, maintenance or replacement is required, and there is always no obvious sign that the equipment does not meet the standard performance. Regular testing can prevent the possibility of poor performance.

Compressed air quality is an important aspect of hygiene in the food industry. Although regulations are still in their infancy in some places, the core desire to protect consumers is enough to ensure regular air testing and ensure that equipment and processing environments can operate efficiently. Although testing will increase costs, it can prevent greater damage or event costs.

Food, compressed air, testing, evaluation, product, control, system, control, hazard, air

Previous Page

Meet at "Road Transport Vehicle Show"

2024-03-11

2024-03-11

Gems president to visit our company exchange

2024-03-11